Jan. 28, 2019 | 10:35:12

With the development and generalization of China's CNC numerical control industry, the production and manufacture of many products are completed by CNC machining. However, tool costs are difficult to control during machining. So how can we reduce the cost of CNC tools without affecting product quality/processing efficiency? Today CNC Lathe Parts Supplier will tell you the answer.

1. Change the traditional business philosophy and choose high quality tools. Many companies blindly reduce the procurement cost of tools and ignore the quality of the tools, resulting in frequent broken tools, knives, new knives, long tool life, rework, and scrapped tools. A vicious phenomenon that leads to a reduction in the quantity of purchases, the increase in costs, and the reduction in processing efficiency and quality. The use of high-quality tools on the surface to see the increase in procurement costs, in fact, the overall processing efficiency is improved, and the production costs are reduced.

2. Select the tool according to the material being processed. Many of the knives on the market are manufactured and manufactured in the form of OEMs. The single category cannot be used to match the materials to the customer and cause customer losses. The FULAIKE brand cutters can be configured according to the materials (such as general mold steel / heat treatment mold / stainless steel parts / aluminum parts / aluminum parts / rubber series soft materials)

3. Select the tool according to the company's machine tool. Nowadays, many companies have combined high-speed machine/CNC machining center/carving machine to process, and matching the tool performance is the key to reducing costs. (For example, the general tool can be used on the CNC but not for the high-speed machine. On the contrary, the high tool cost can not achieve good results).

4. Make full use of the position of the CMC captain. In the production process, let it control the reasonable arrangement and deployment of the tool.

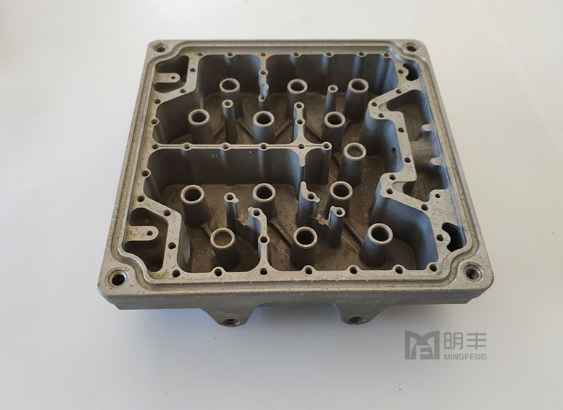

We are also Die Casting Parts Wholesaler, if you want to process metal parts, you can contact us directly, we will customize according to your drawings.